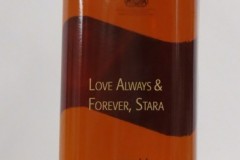

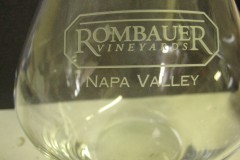

We specialize in sandblasting (also knowm as sandcarving) glass, crystal, granite and marble From awards, glassware and decanters to urns in marble and granite we have been sandblasting for over 20 years. All of our sandblasting is done in house to give you fast turnaround

Sandblasting involves using compressed air to force a stream of abrasive through a nozzle and onto the glass to etch or carve a design. Versatility and superior end results are the primary reasons for choosing this marking method. With sandblasting, you can achieve just about any look you want on any type of glass, crystal, granite or marble.

It has become common to use only a laser to personalize these awards, but sandcarving results in very smooth, crisp lines as it does not fracture the glass like other engraving methods, which can result in chips or cracks on the edges of etched lines. While laser engraving and diamond cutting both have their benefits, laser engraving cannot go very deep and diamond cutting cannot produce a well-defined edge. With sandblasting, you get both.

Invalid Displayed Gallery